Why rubber flooring matters

In equestrian facilities, flooring is critical for both animal welfare and daily maintenance.

FEROX mats and tiles help prevent slipping, reduce joint stress and simplify cleaning — all while maintaining excellent durability under heavy use.

- Comfort & joint protection

- Non-slip & hygienic

- Noise & vibration reduction

- Easy to clean & maintain

Looking for something unique?

Whether you want a specific hardness for shock absorption, a reinforced inlay for high-load zones, or an embossed logo for private labeling — we make it possible.

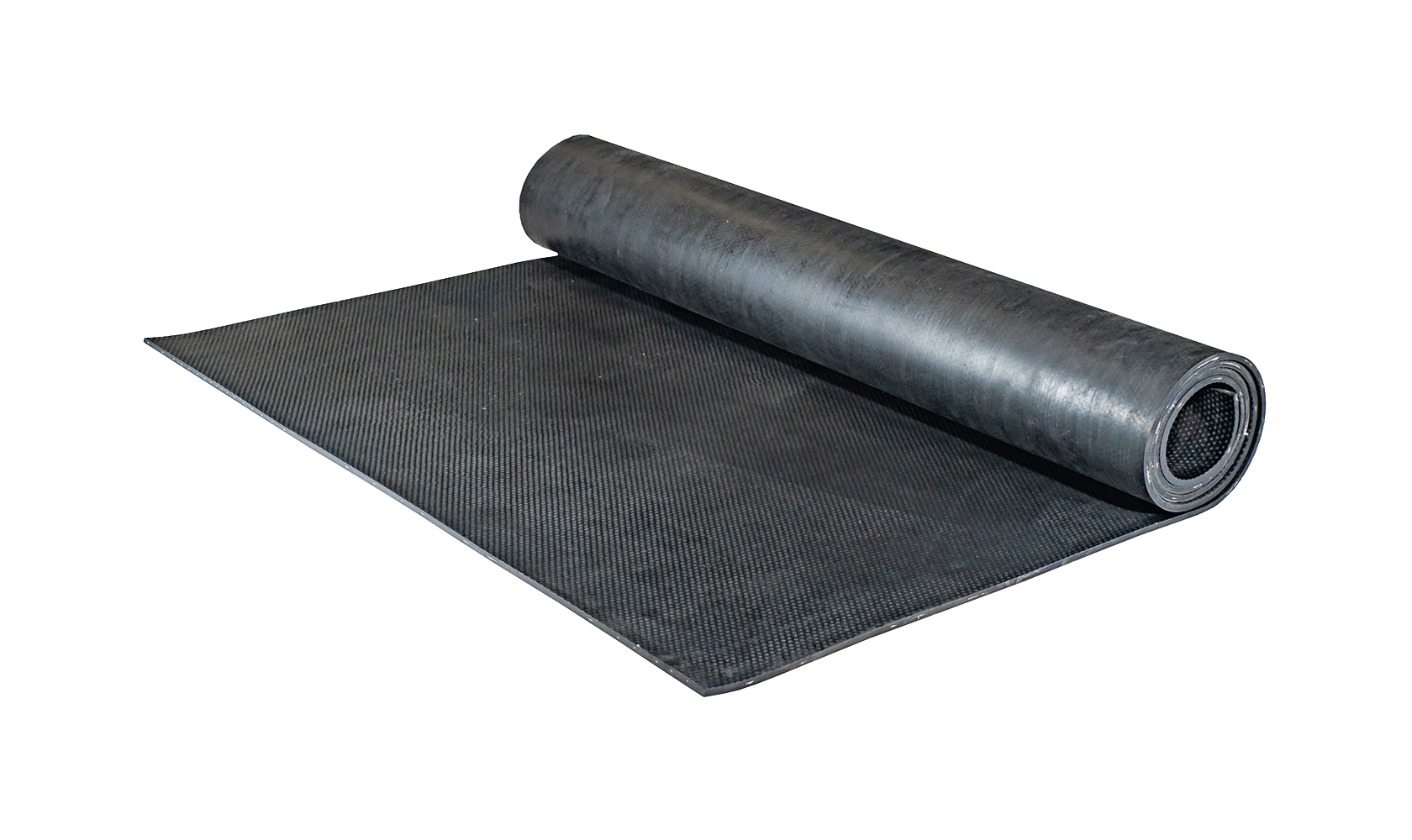

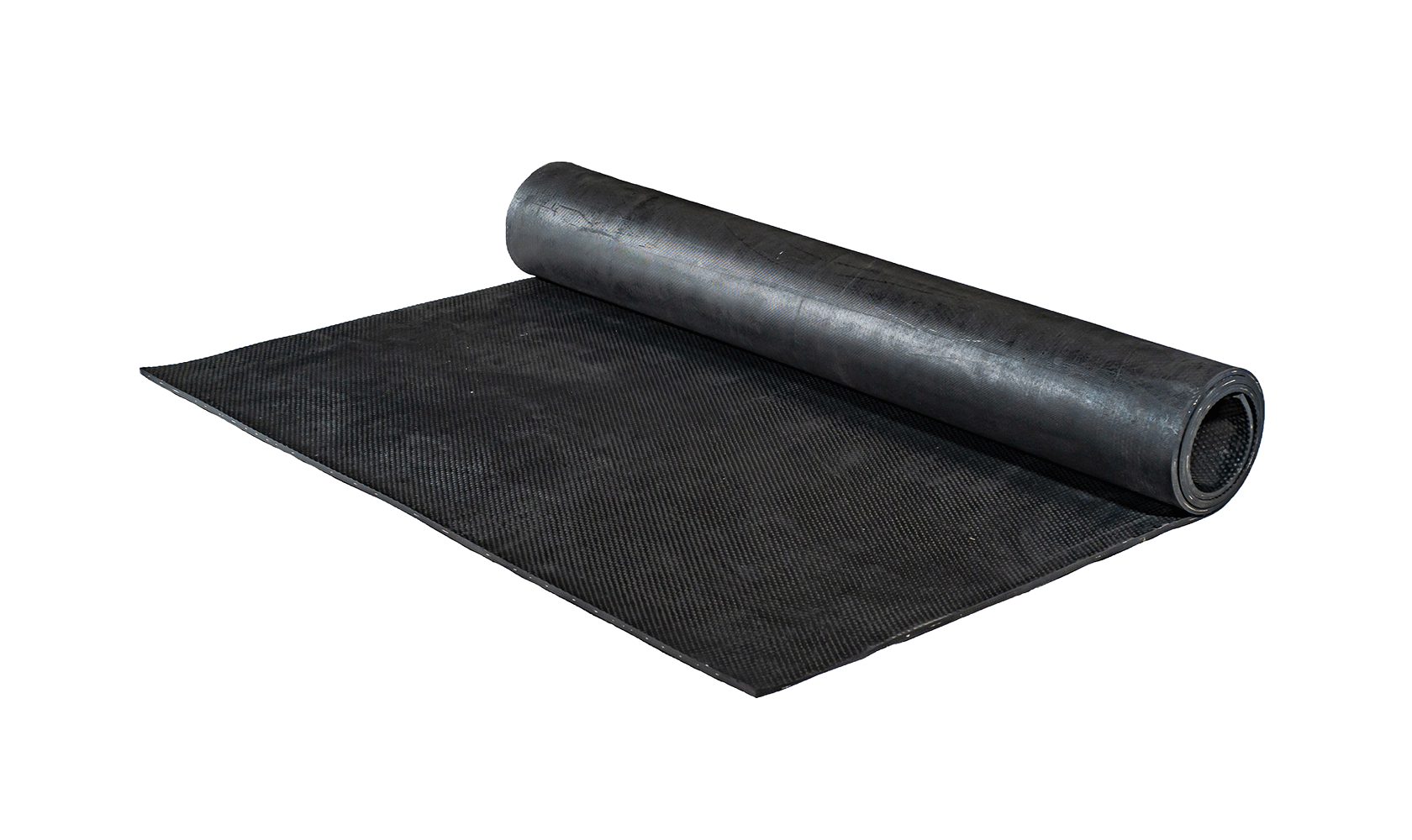

- All sizes and thicknesses. Rolls up to 520cm wide!

- Various top and bottom profiles (Hammer, studded, ribbed, smooth)

- Big Jumbo mats for seamless one-piece stable box flooring

- Special sheets and rolls for stable box walls

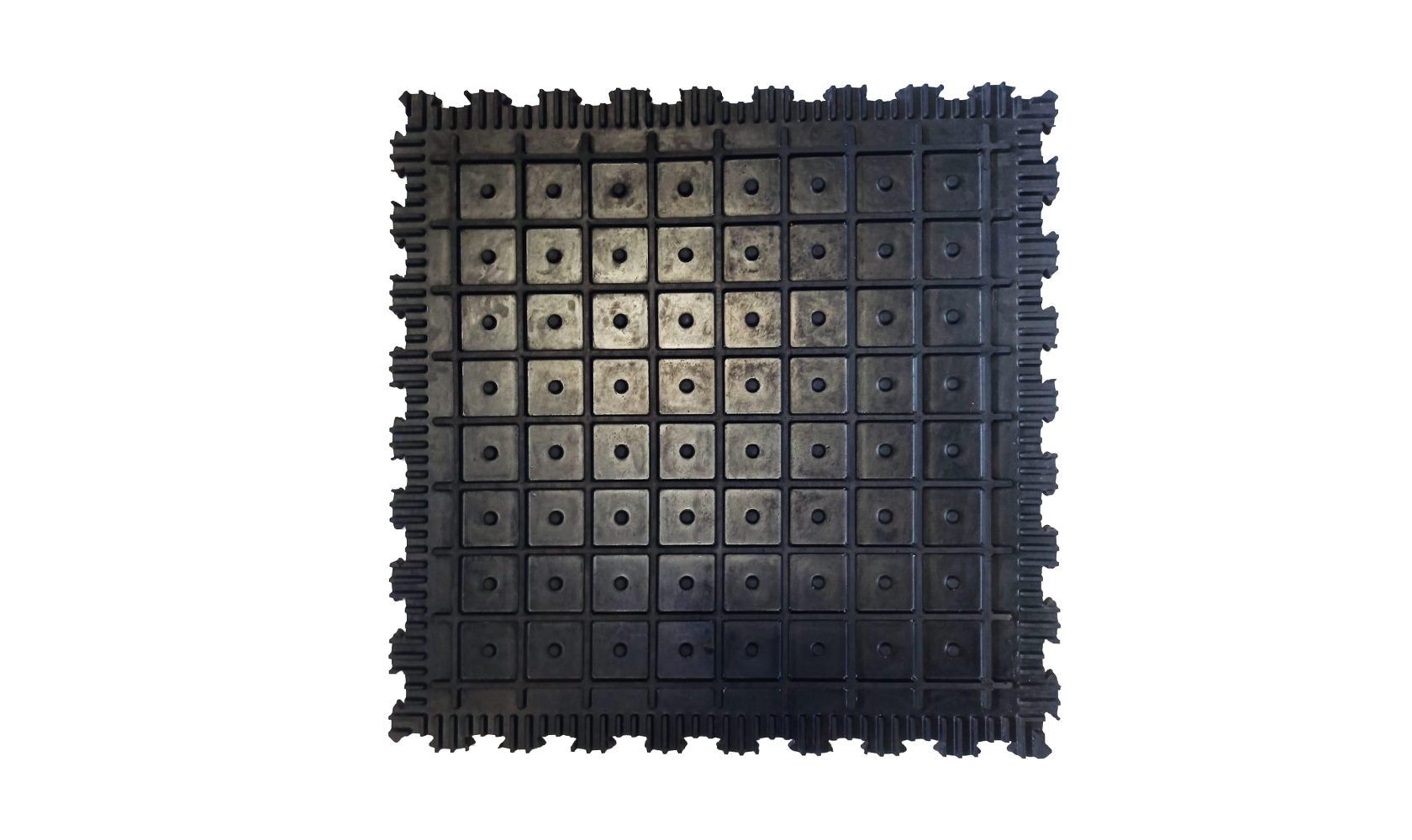

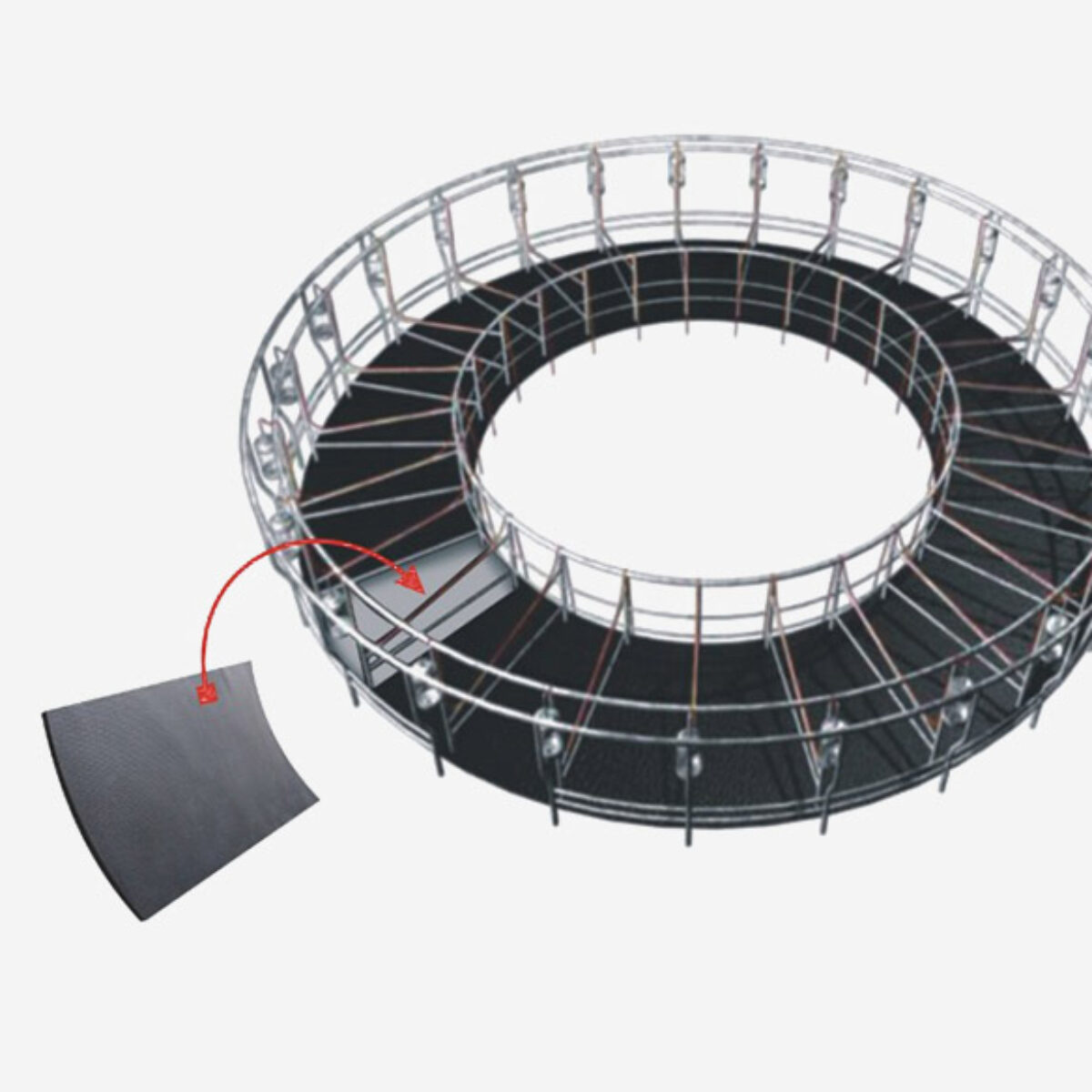

- Puzzle Mat solutions for easy installation

- Private label branding and packaging

- Various Ramp Mats, single or rolled

- Excellent custom trailer flooring options

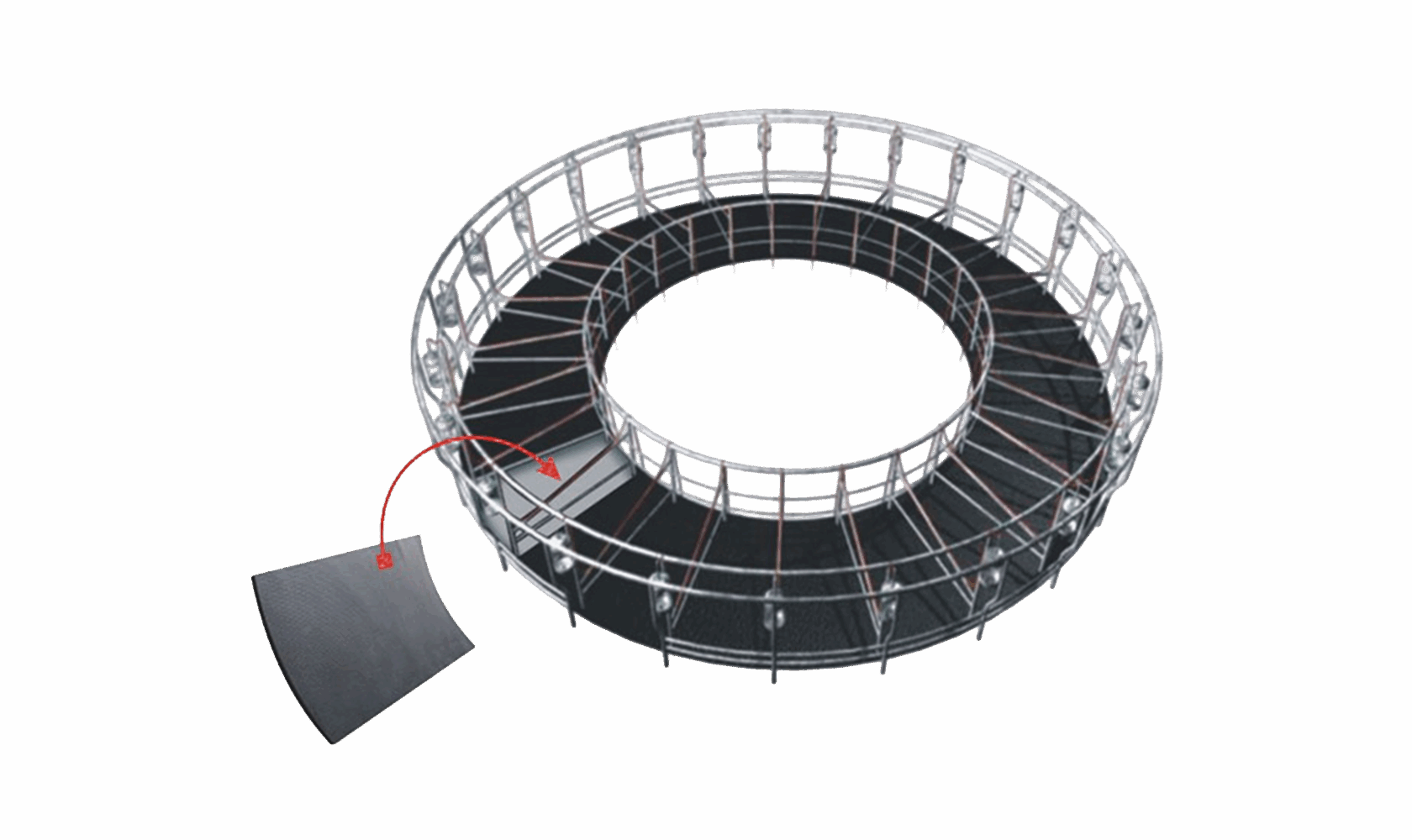

Recommended flooring for equine environments.

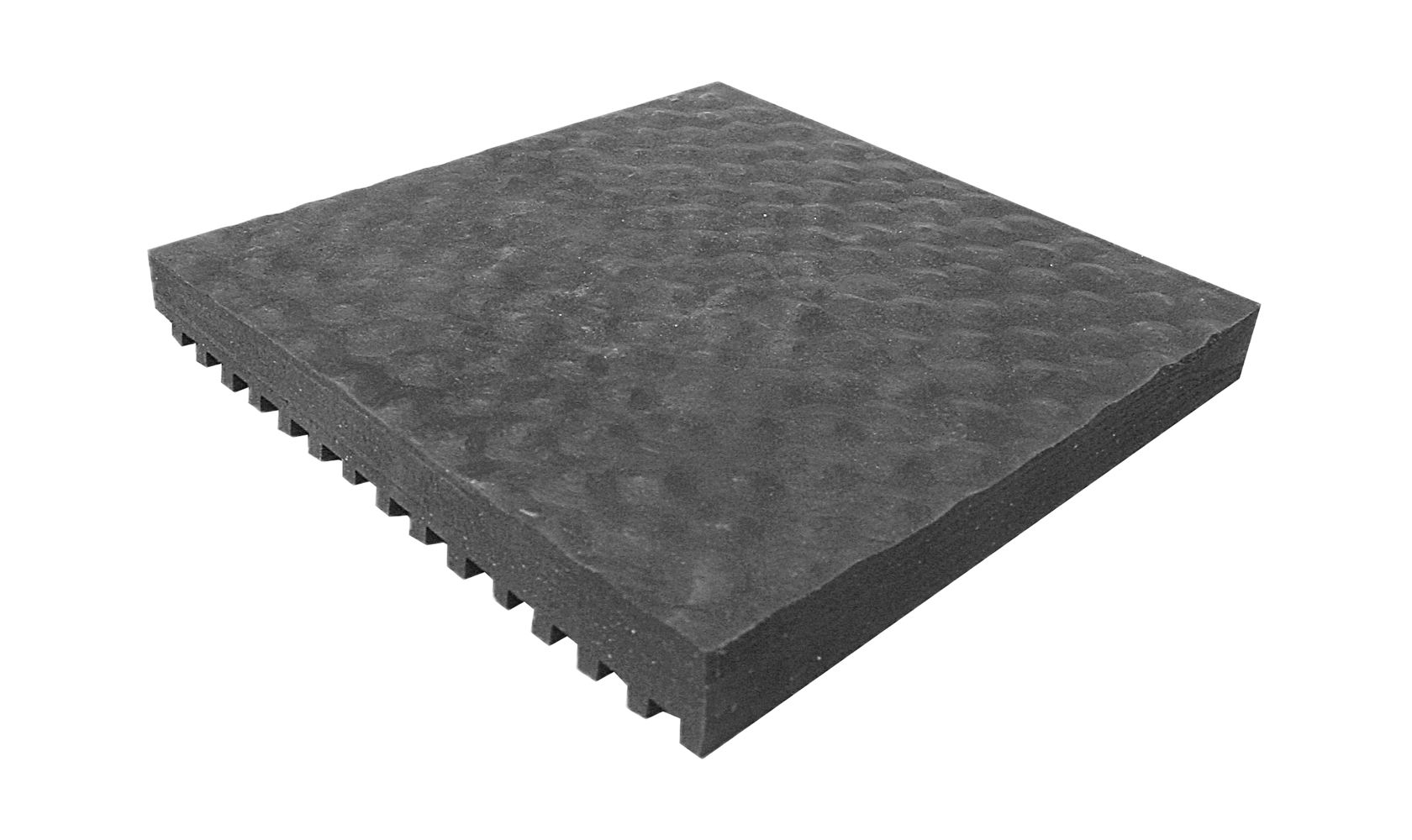

- Rolled Stall MatsDurable hammer-top rolled rubber mats for dairy alleys and lying boxes, horse stable alleys and horse boxes, trailers, passages and parlours.

- Puzzle MatsInterlocking rubber mats designed for stable boxes, corridors, small livestock areas and utility zones.

- Comfort Puzzle MatsComfortable premium puzzle for your horse box

- Stall KitsSets of puzzles specially designed for horse boxes

- Trailer Floor MatsOur mats are the perfect solution for the flooring of any animal trailer. Highly slip-resitant, strong, and not too heavy.

- Ramp MatsOur high-end ramp mats can be delivered in sheets as well as on roll, the mats make sure your horses or other animals can enter and leave your trailer or truck safely.

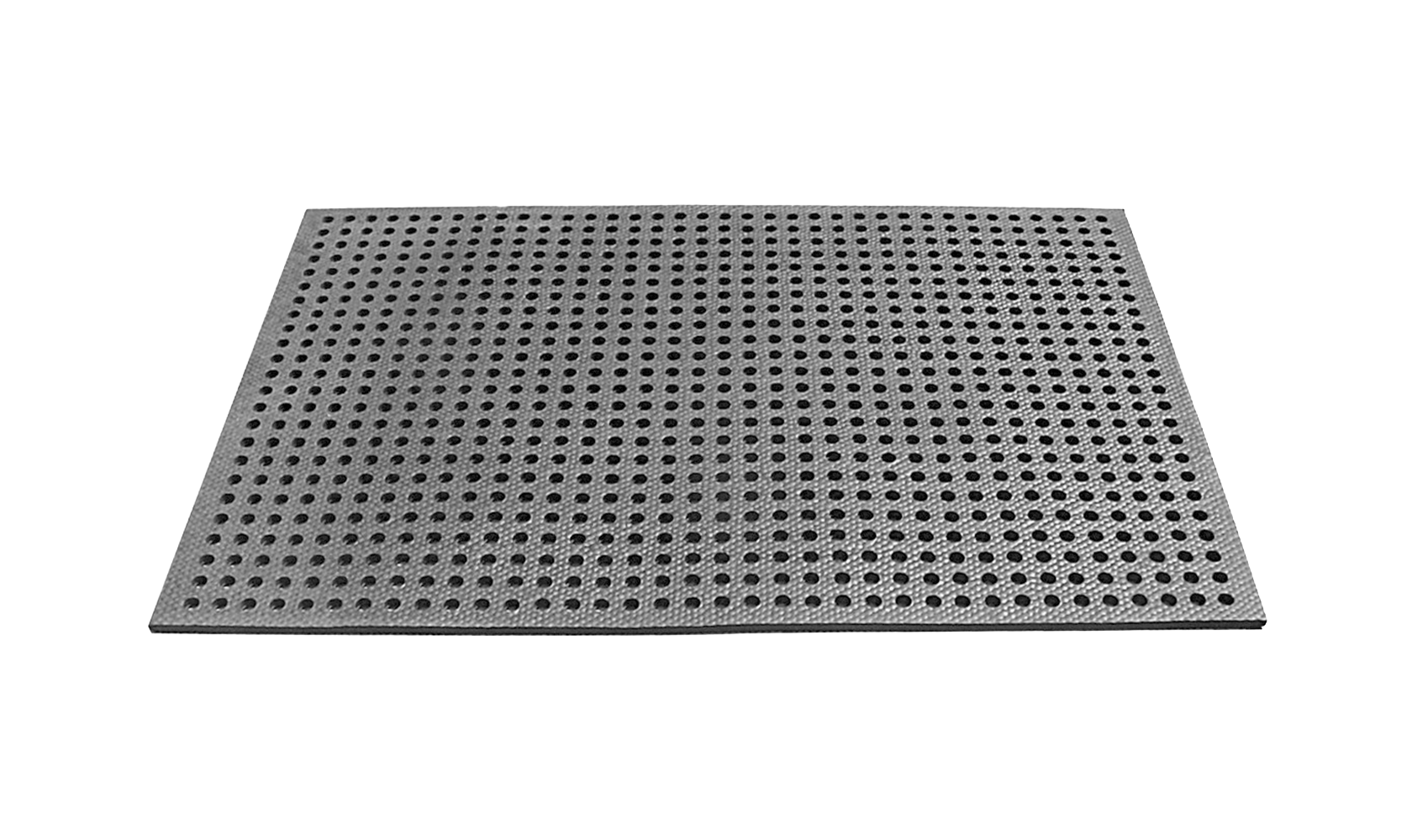

- Stall Mat with HolesMade from high-quality natural rubber with excellent grip and stability

- Basic Stall MatsHeavy-duty sheets for boxes, corridors and washing areas.

Performance & Benefits

- Animal comfortSoft elasticity improves rest and recovery while reducing stress injuries.

- DurabilityWithstands hoof impact, cleaning agents and temperature changes.

- Drainage & hygieneStructured bottoms and optional perforations allow liquids to flow easily.

Frequently asked questions

From stall mats and ring mats to studded rolls and ramp flooring — every FEROX product is built for long-term performance, maximum comfort and reliable grip.

Our standard MOQ is typically one fully loaded sea container. Mixed containers with multiple products can be arranged. Introduction through Pallet-wise delivery is available upon request.

Yes — every product can be made to your exact size, width, and thickness, as well as further specifications. We can our proud to be able to offer rolled mats in any thickness, any length, and any width up to 520cm!

Absolutely. Together with our production partner Supranusa Rubber, we can adjust hardness, tensile strength, elongation and any other requirements. Just let us know what you want!

Yes — we produce embossed or printed logos, custom labeling and private-label packaging for distributors and OEM partners.

Lead times depend on order type, size and customization level. Typical production time is 3–7 weeks from order confirmation. We’ll always confirm your timeline before production starts. Shipment time depends on many factors, such as your location, and the current container shipping situation.